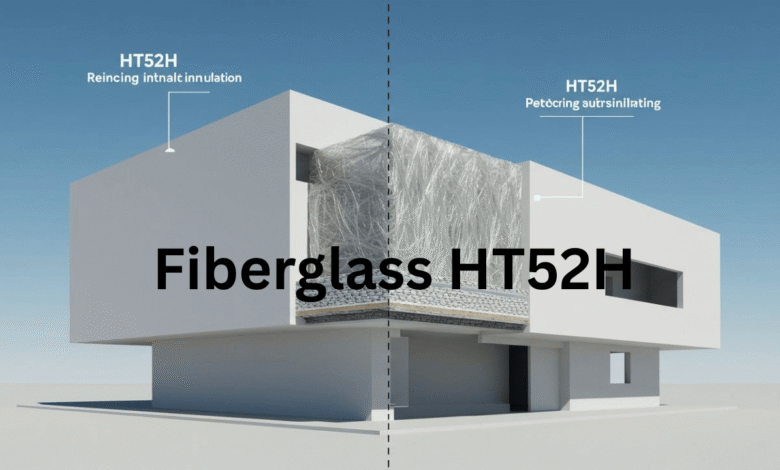

Fiberglass HT52H High Temperature Fabric for Industrial Applications

Fiberglass ht52h is a high-performance treated satin weave fiberglass fabric designed to withstand extreme temperatures and provide reliability in demanding environments. Unlike standard fiberglass that usually performs up to 800°F, fiberglass ht52h is engineered to endure continuous temperatures up to 1200°F. This makes it a go-to solution in industries where heat resistance, durability, and flexibility are essential.

Developed under the Flxglas HT specialty line, this fabric has become an important choice for industries such as automotive, marine, oil and gas, military, petrochemical, and power generation. Its unique properties make it suitable for products that must operate in environments where heat management is a critical factor.

Physical Specifications of Fiberglass HT52H

The physical specifications of fiberglass ht52h highlight why it is trusted for high-temperature use. It comes in widths of 38 inches and 60 inches, with a standard roll length of 50 yards. The material thickness is approximately 0.055 inches, and it carries a weight of about 52 ounces per square yard. Typically available in a tan color, it provides a balance of strength and flexibility while maintaining a manageable structure for different industrial applications.

The satin weave construction enhances the mechanical performance of fiberglass ht52h. This weave ensures excellent flexibility while still maintaining structural integrity under constant exposure to elevated temperatures. The thickness and weight make it robust enough to protect equipment, yet it remains pliable enough to be shaped or fitted as required.

Temperature Resistance and Performance

One of the most significant features of fiberglass ht52h is its ability to endure continuous exposure to heat. Standard fiberglass materials begin to weaken above 800°F, but this fabric remains strong and reliable up to 1200°F. The treatment process it undergoes ensures that the fibers maintain their strength and do not deteriorate under prolonged exposure to extreme heat.

This makes fiberglass ht52h especially suitable for products exposed to fluctuating or continuous high temperatures. Whether used in machinery insulation or thermal protective covers, the material retains its properties, preventing equipment damage and ensuring safety. The combination of strength, temperature resistance, and flexibility positions it as one of the most advanced high-temperature fiberglass fabrics available.

Industrial Applications of Fiberglass HT52H

Fiberglass ht52h is applied in a wide variety of industries due to its versatility. Some of the most common uses include:

- Expansion joints in pipelines and ducting systems where constant heat and movement require a fabric that can flex without losing strength.

- Tube seals and insulation pads where the material must fit securely and endure repeated thermal cycles.

- Thermal insulation wraps and protective covers for heavy machinery and equipment in oil refineries and power plants.

- Marine and automotive applications where engines and exhaust systems produce high levels of heat.

- Military and defense products where heat resistance and durability are critical for safety and performance.

In each of these applications, fiberglass ht52h delivers long-term durability, reducing the need for frequent replacements and lowering maintenance costs.

Advantages of Fiberglass HT52H Over Standard Fiberglass

Fiberglass ht52h offers several benefits when compared to standard fiberglass fabrics:

- Continuous use up to 1200°F compared to around 800°F for regular fiberglass.

- Satin weave design that allows greater flexibility and resistance to wear.

- Maintains both strength and flexibility even in environments where heat is constant.

- Available in convenient roll lengths and widths, making it easier for manufacturers to use.

- Proven performance in some of the harshest industrial environments worldwide.

These advantages make fiberglass ht52h a superior choice for industries where both reliability and performance matter.

Factors to Consider When Choosing Fiberglass HT52H

When selecting fiberglass ht52h for industrial applications, several factors should be kept in mind:

- The specific temperature requirements of your application.

- The need for flexibility in the final product such as in seals or joints.

- The required durability for long-term performance in high-stress environments.

- The dimensions of fabric needed based on machinery or equipment size.

Understanding these factors ensures that fiberglass ht52h is implemented effectively, maximizing its benefits while fitting the technical requirements of the project.

Key Industries Benefiting from Fiberglass HT52H

Many industries benefit from the advanced properties of fiberglass ht52h. In the petrochemical and oil and gas industries, the fabric protects systems from heat damage, ensuring operational safety. In the power generation sector, it is used to insulate turbines and engines. Automotive and marine applications rely on it for protecting exhaust systems and engines from excessive heat.

The military and defense sector often uses fiberglass ht52h in protective barriers and equipment coverings where safety and resilience are paramount. Heavy machinery industries also depend on it to protect operators and equipment, minimizing downtime caused by heat-related issues.

Why Fiberglass HT52H Stands Out in High-Temperature Fabrics

While many materials are designed to handle high heat, fiberglass ht52h stands out because it provides a rare combination of high temperature tolerance, flexibility, and strength. Some fabrics may offer heat resistance but lack durability, while others may be strong but rigid. This material bridges that gap, making it reliable across multiple industries with varying demands.

Its satin weave design ensures not just durability but also usability, making it easier for manufacturers to adapt the fabric into different shapes and applications. This adaptability has positioned fiberglass ht52h as one of the preferred materials in the high-temperature fabric category.

Practical Benefits in Industrial Use

The use of fiberglass ht52h provides both immediate and long-term benefits. Equipment experiences less thermal stress, which extends operational life. Companies save costs by reducing replacements and maintenance. Workers and operators are better protected from heat-related risks. The material also provides a level of assurance that systems will remain reliable even in demanding environments.

Conclusion

Fiberglass ht52h is not just another fiberglass fabric; it is a specialized high-temperature solution designed to meet the toughest industrial challenges. With its ability to withstand continuous heat up to 1200°F, its flexible satin weave construction, and its proven applications across industries, this fabric has established itself as a leader in high-performance insulation materials.

Industries ranging from petrochemical to automotive and from marine to military depend on fiberglass ht52h for its unique combination of strength, heat resistance, and flexibility. By understanding its specifications, applications, and advantages, businesses can make informed decisions about using this material to improve safety, efficiency, and performance in their operations.

Frequently Asked Questions About Fiberglass HT52H

1. What is fiberglass ht52h?

Fiberglass ht52h is a treated satin weave fiberglass fabric designed for high-temperature environments. It can handle continuous exposure to heat up to 1200°F, making it suitable for demanding industrial applications such as insulation, expansion joints, and protective covers.

2. How is fiberglass ht52h different from standard fiberglass fabric?

Unlike standard fiberglass, which typically withstands temperatures up to 800°F, fiberglass ht52h is engineered to perform at much higher heat levels. It also offers better flexibility and durability due to its satin weave construction, making it more versatile for industrial use.

3. What industries use fiberglass ht52h?

Fiberglass ht52h is widely used in industries such as automotive, marine, military, petrochemical, oil and gas, heavy machinery, and power generation. It is applied in areas where heat resistance and strength are critical for safety and performance.

4. What are the physical specifications of fiberglass ht52h?

Fiberglass ht52h is available in 38-inch and 60-inch widths, with standard roll lengths of 50 yards. It has a thickness of about 0.055 inches and a weight of approximately 52 ounces per square yard. The fabric is generally tan in color.

5. What makes fiberglass ht52h suitable for expansion joints and seals?

The satin weave design of fiberglass ht52h allows it to remain flexible while retaining strength under heat and movement. This makes it ideal for expansion joints, tube seals, and similar components that experience constant motion and thermal cycles.